How to Cut Pool Fence Mesh – DIY Method 3: Double Molding Cut

When installing or modifying a mesh pool fence, there may be times when you need to shorten a section to match your layout. There are three main ways to cut a mesh fence: Trim to Fit, Border Trim & Tape, and the most secure option—Double Molding Cut.

Whether you’re a DIYer or a professional installer, this method gives you a clean, strong, and long-lasting result. It does take a little more effort and some extra parts, but the result is worth it.

Tools & Materials You’ll Need:

- Cordless drill

- #2 Phillips bit (Classic) or #2 Square Drive bit (Ultra)

- Tape measure

- China marker or grease pencil

- Scissors

- One extra molding per cut

- Two ¾” screws per cut (in addition to the normal section screws)

When to Use This Method

Use the Double Molding Cut when you:

- Want the cleanest and most durable finish

- Are cutting a section at a termination point, wall, or gate

- Need a professional-grade repair or layout modification

- Don’t mind using extra moldings and screws

Step-by-Step Instructions

1. Remove Existing Molding

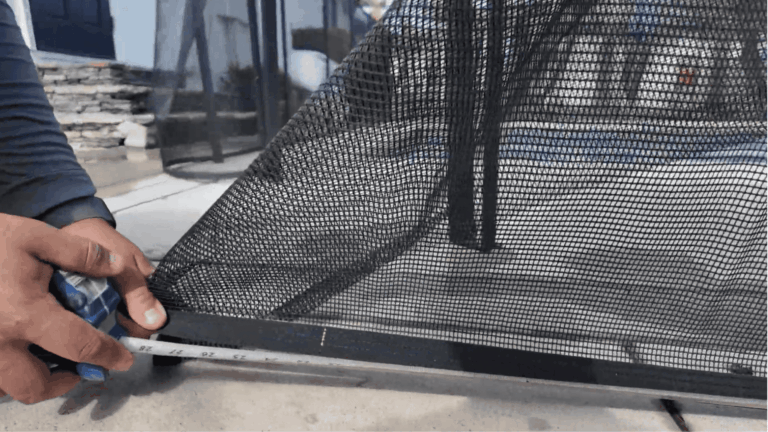

Unscrew and remove the existing molding from the pole you’re cutting. Trim off any excess mesh but leave at least 8 inches of slack to grip and stretch the mesh.

2. Mark Your Cut Line

Wrap the bottom mesh border tightly around the pole.

Use your China marker to mark the center of the pole on the mesh.

Measure the distance from the previous pole’s mark and transfer that measurement to the top border to keep your cut straight.

3. Attach the First Molding

Pre-set a ¾” screw into the top hole of the molding.

Hold the molding in place so the top mesh border sits slightly above the top of the molding.

Screw through the mesh into the pole at your marked center point.

Pro Tip: Keep your fingers out of the path of the screw—always screw between them.

4. Create the Double Molding Sandwich

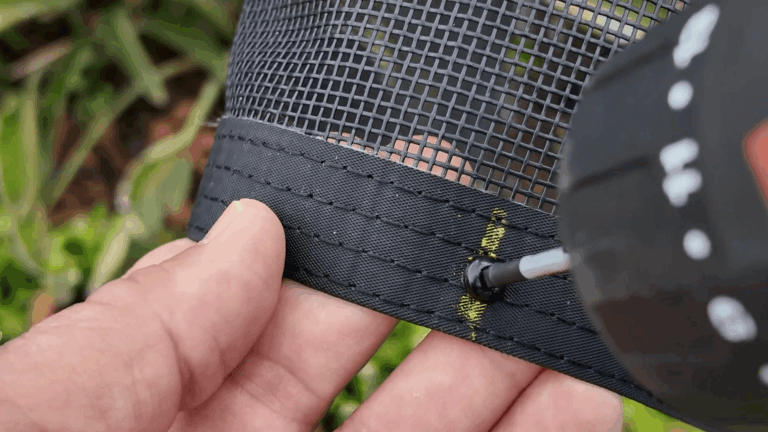

Place your extra molding on the back side of the mesh.

Fold the slack mesh over and screw through both moldings and the folded-over mesh.

Finish attaching both moldings and mesh to the pole.

5. Set the Bottom Screw

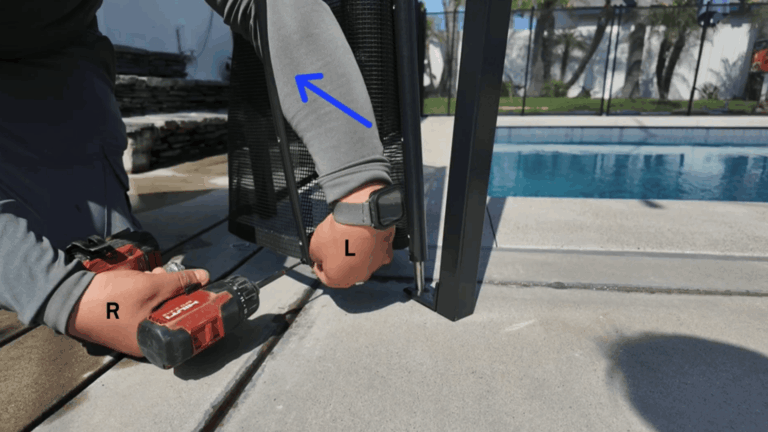

Pre-drill the mesh just above the second thread from the bottom.

Pre-set a ¾” screw into the bottom hole of the molding.

With your drill in your right hand, push into the pole while holding the bottom mesh border with your left hand.

Use your arm between the mesh and molding to create a slight arch, which helps eliminate wrinkles as you drive the screw.

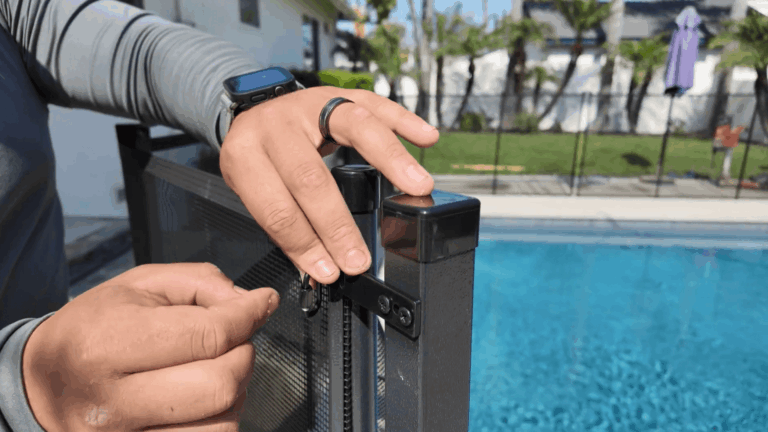

6. Reinstall the Pole and Complete the Section

Push the pole back into the deck sleeve.

Reconnect the fence section.

You can now finish the cut using standard section screws for the remaining border attachment points.

Final Steps: Tighten and Trim

Pull the remaining mesh tight between the poles.

Start from the middle of the molding, drive the first screw, and work your way down, pulling the mesh as you go.

Then work upward from the center.

Once all screws are secure, carefully cut off the excess mesh using scissors.

That’s the Double Molding Cut

Strong, professional, and effective — this method gives you a high-quality result that holds up over time. For other cutting options, check out:

Trim to Fit – No Materials Needed

Border Trim & Tape – Quick & Clean DIY

Need extra moldings, screws, or tools? Shop pool fence parts here »